Yard Shuttling Services: Streamline Your Trailer Movement And Yard Flow

Running a busy yard without a plan can feel like trying to solve a puzzle with missing pieces. The same thing goes when trailers are waiting and docks are full; your team is stuck fixing problems instead of staying on track.

That’s where yard shuttling services come in. These services focus on moving trailers inside your facility. They keep everything flowing by ensuring the right trailer is in the right place at the right time.

If you’re running a warehouse, distribution center, or industrial site, shuttling isn’t just a support task. It’s a core part of maintaining yard order and meeting your schedules.

What Are Yard Shuttling Services?

Yard shuttling services are all about keeping things moving inside your facility. It relies on dedicated trucks and skilled drivers, often referred to as yard spotters or yard jockeys, to move trailers between different points within the yard. This includes shifting trailers from drop zones to loading docks, staging areas, or exit lanes, based on priority and schedule. Unlike long-haul trucking, shuttling stays within your property.

In short, yard shuttling services help your yard run smoother by taking charge of trailer movement. This avoids backups, reduces wait times, and keeps your loading schedule on track.

Why Yard Shuttling Services Matter

Every minute a trailer sits in the wrong place, your yard loses time and money. Yard shuttling services keep trailer movement organized and predictable. They help you stay on top of schedules, reduce chaos, and keep operations flowing smoothly. These services help to:

- Minimize trailer idle time and reduce dwell costs

- Keep docks accessible for scheduled loading and unloading

- Prevent traffic congestion inside the yard

- Improve communication between dispatch and yard teams

- Enhance safety by reducing blind moves and last-minute changes

- Boost driver satisfaction by cutting unnecessary wait times

- Help maintain compliance with time-sensitive carrier appointments

How Yard Shuttling Services Keep Operations On Track

Yard shuttling keeps trailers moving inside your facility so nothing falls behind. By getting trailers to the right dock at the right time, it helps avoid delays, keeps loading on schedule, and makes sure your yard runs smoothly.

Below are a few ways this process supports daily operations:

-

- Reduce Congestion: Idle trailers are quickly relocated, clearing space and preventing traffic jams

- Improve Dock Utilization: Docks stay busy without being overwhelmed. Trailers are staged and rotated as needed

- Enable Accurate Scheduling: When movement is predictable, load times become easier to plan and stick to

- Cut Labor Waste: Warehouse staff don’t have to search for trailers or wait on late dockings; they stay focused on loading and unloading

- Support 24/7 Operations: Night or day, yard shuttle drivers keep your yard running like clockwork

With the right yard shuttling plan, your yard becomes a crucial part of your supply chain’s success.

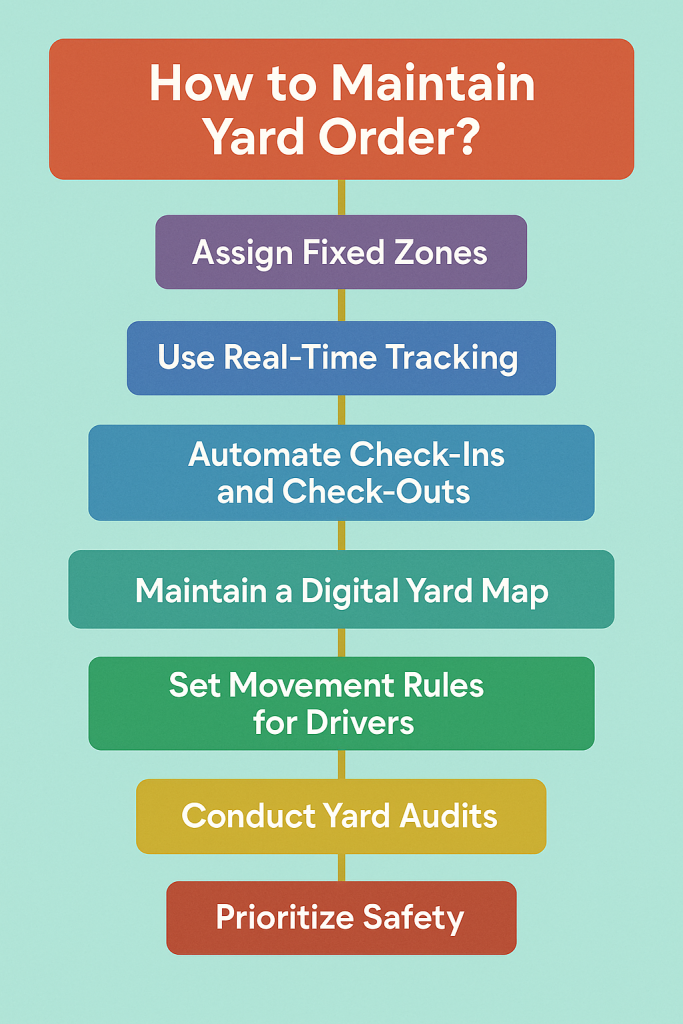

How To Maintain Yard Order?

A yard without structure quickly becomes chaotic. But when every space and move is planned, even the busiest yards stay under control. Keeping the yard in order means giving everything a proper place and making sure each move has a reason. With a clear layout and simple rules, even a busy yard can run smoothly without a mess.

Below are simple but powerful ways to keep your yard operations clean and under control:

Assign Fixed Zones

Divide your yard into dedicated areas for inbound, outbound, empty, and loaded trailers. Label zones clearly so drivers and staff know exactly where to park, drop off, or pick up without confusion.

Use Real-Time Tracking

Implement radio frequency identification (RFID) tags, GPS sensors, or barcode systems on all trailers. Connect these to your yard management system (YMS) so every trailer’s location, status, and movement history is visible.

Automate Check-Ins And Check-Outs

Set up digital gatehouse systems that log trailer arrivals and departures automatically. This reduces paperwork, prevents unauthorized movement, and improves yard flow accuracy.

Maintain A Digital Yard Map

Use a live dashboard to view trailer positions, available spots, and traffic patterns. This helps prevent parking overlap and gives dispatchers more control over daily operations.

Set Movement Rules For Drivers

Standardize trailer handling with step-by-step protocols, such as where to drop, how to log a move, and when to report maintenance. It cuts confusion and keeps operations safe.

Conduct Yard Audits

Weekly or bi-weekly yard walk-throughs help spot inefficiencies like misplaced trailers, blocked lanes, or underused zones. Regular audits keep the layout aligned with real-world needs.

Prioritize Safety

Mark all traffic lanes, install proper lighting, and assign safety marshals during peak hours. An orderly yard is a safer yard.

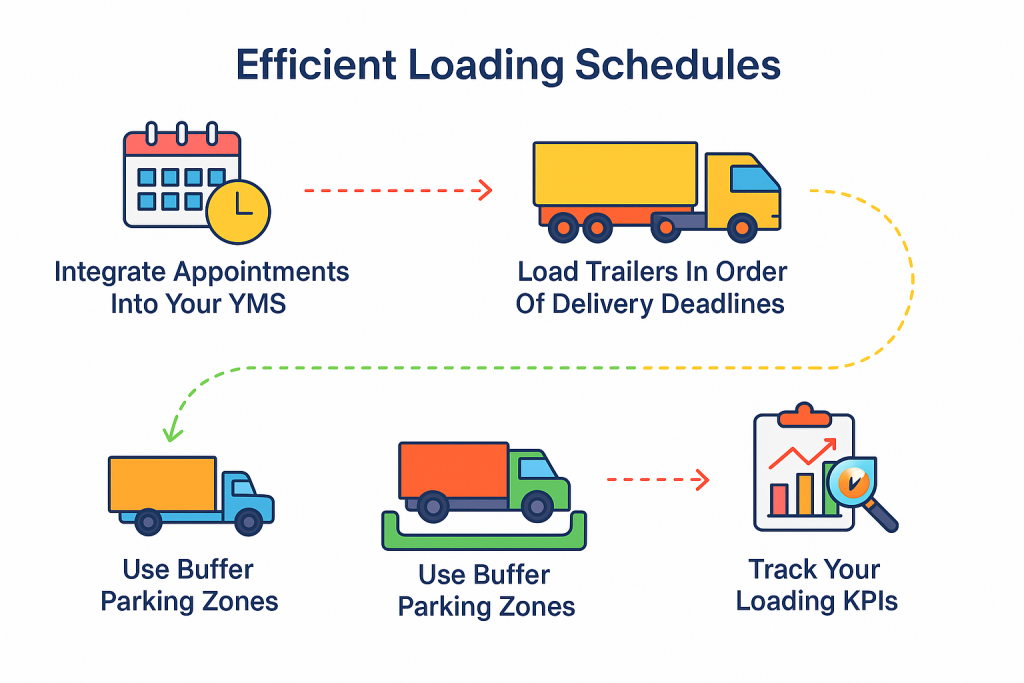

How To Maintain Efficient Loading Schedules

When trailers pile up and docks stay idle, it’s a sign your loading schedule needs attention. The goal isn’t to rush but to create a system where every trailer, team, and dock operates in sync. Follow the tips below to stay on schedule:

Integrate Appointments Into Your YMS

Don’t allow trucks to show up unannounced. Use a (YMS) system that includes appointment scheduling so you can control who arrives, when, and at which dock. This prevents double-bookings and keeps dock doors in constant use.

Load Trailers In Order Of Delivery Deadlines

Organize your loading sequence based on when shipments need to leave, not just when they arrive. Prioritize outbound trailers that are due first and make sure they’re staged ahead of time. This avoids last-minute rushes and failed time slots.

Use Buffer Parking Zones

Set up holding areas near your loading bays where trailers can be pre-staged before their scheduled time. That way, your crew doesn’t waste time locating or repositioning trailers at the last second.

Track Your Loading KPIs

Keep an eye on numbers that actually matter:

- Gate-to-dock time (how long trailers wait to reach a dock)

- Trailer dwell time (how long trailers stay in the yard before or after loading)

If these numbers are high, your schedule needs tightening. Use them to spot patterns and prevent repeat delays.

Align Shuttle Moves With Warehouse Crew

Timing is everything. Make sure your yard shuttling and warehouse teams are working off the same schedule. If a shuttle drops off a trailer but no one’s available to load it, time is wasted. Coordinate shifts, breaks, and trailer moves with clear visibility across teams.

Challenges In Yard Shuttling Operations

Even with the right systems in place, yard shuttling comes with its own set of complications. From scheduling gaps to lack of visibility, these hurdles can stall productivity and inflate operating costs if left unaddressed. Recognizing these issues early helps you build stronger, more resilient operations.

- Downtime Disruptions: Unplanned equipment breakdowns or slow trailer swaps can halt shuttle activity, creating delays that ripple through the yard and into outbound delivery schedules

- Increased Fuel Expenses: Short hauls still burn fuel. Without route planning or fuel-efficient vehicles, frequent shuttle moves add up. Especially when performed inefficiently or on demand without batching

- Manual Administration: Many yards still rely on whiteboards, paper logs, or verbal updates. This outdated approach increases errors, slows down decisions, and reduces real-time awareness of trailer locations or statuses

- Unsafe Driver Behavior: Lack of training, unclear traffic rules within the yard, or rushed moves can lead to minor accidents, equipment damage, or injury, all of which cost time and money

- Compliance Complexity: Keeping up with DOT regulations, emissions standards, and labor compliance (like rest breaks or shift limits) is difficult when shuttle moves aren’t well-documented or tracked

5 Key Benefits Of Yard Shuttling Services

Yard shuttling does more than just move trailers, it creates structure, reduces costs, and speeds up your overall logistics chain. When done right, it turns your yard into a strategic asset instead of a bottleneck.

1. Better Vehicle Uptime

By keeping trailers moving in and out on time, shuttling reduces idle periods, ensuring your equipment is used efficiently rather than sitting in the lot.

2. Reduced Operating Costs

Efficient trailer transfers lower detention fees, cut fuel waste, and eliminate the need to assign long-haul drivers to short yard tasks.

3. Greater Visibility

With shuttle movements tracked through a YMS, dispatchers always know where trailers are, what’s inside, and which ones are next in line.

4. Safer Driving Habits

Structured shuttle routines with trained drivers and clear yard traffic rules reduce the chance of accidents or damage to equipment.

5. Easier Regulatory Compliance

Yard shuttling operations that are logged digitally help meet DOT, safety, and emissions standards by providing reliable documentation.

Which Companies Can Use Yard Shuttling To Stay Efficient

Yard shuttling is not just for large enterprises. However, it benefits any business that moves a high volume of trailers or operates across multiple locations. Below are the types of companies that gain the most from shuttle services:

- Manufacturing Companies: To transfer trailers between production facilities, raw material storage, and outbound docks without delays

- Retail And E-commerce Warehouses: To handle trailer overflow during seasonal peaks and maintain constant inventory movement

- Cold Chain And Food Distributors: To move refrigerated trailers quickly and safely between cold zones and loading bays

- Third-Party Logistics (3PL) Providers: To reposition client-owned trailers across complex yard networks efficiently

- High-Volume Distribution Centers: To maintain fast trailer turnover even in yards with limited dock availability

Final Thoughts: What Makes Yard Shuttling A Smart Move

Yard shuttling may seem like a small part of logistics, but its impact reaches every corner of your operation. When done right, it cuts delays, improves trailer visibility, and frees up dock space, without requiring major infrastructure changes.

Whether you’re running a high-volume yard, managing cold-chain freight, or simply dealing with trailer overflow, shuttle services give you more control over time, space, and labor. It’s a practical and scalable solution that pays off in terms of efficiency and cost savings.

Ready to take control of your yard? Explore our yard shuttling services for fast, safe, and reliable solutions tailored to your facility’s needs. Contact us today for a customized solution.

This Blog is written by Ayesha Suleman