In the world of industrial logistics and factory operations, every second counts. Delays, inefficiencies, or idle equipment can result in substantial financial losses and disrupted production schedules. One of the most effective ways to minimize such downtime is through professional spotting services.

This article explores what spotting services are, how they work, and why they are essential in optimizing yard management and reducing production downtime.

What Are Spotting Services ?

Spotting services refer to the use of dedicated, on-site personnel (called spotters) who manage the movement and placement of trailers within a facility’s yard. Instead of relying on external drivers or waiting for trucks to arrive, companies that use spotting services have professionals on hand to relocate trailers quickly and efficiently.

These services are commonly used in:

-

Manufacturing plants

-

Distribution centers

-

Warehouses

-

Logistics hubs

By maintaining control over trailer movement, companies can ensure that docks are always loaded or unloaded promptly, and trailers are available exactly when needed.

The Impact of Downtime

Before diving deeper into spotting, it’s crucial to understand the cost of downtime.

Even a 30-minute delay in trailer loading or unloading can result in:

-

Delayed production

-

Overtime costs for staff

-

Missed shipment deadlines

-

Reduced customer satisfaction

The key to avoiding this is to ensure that trailers are always in the right place at the right time. This is where spotting services provide measurable value.

How Spotting Services Reduce Downtime

-

Quick Trailer Movement

Spotters ensure that trailers are relocated promptly from the dock doors to yard spots, and vice versa. This minimizes wait times and ensures the continuous flow of materials. -

Better Yard Organization

Spotters maintain a real-time understanding of trailer locations. With efficient organization, the yard avoids congestion and bottlenecks, which can lead to delays and even accidents. -

Immediate Availability of Trailers

With proper yard planning, spotters make sure that the next trailer is already positioned when the current one is finished. This seamless transition keeps operations moving without interruptions. -

Reduced Dependency on External Drivers

Waiting for external transport drivers to move trailers can be time-consuming. Spotters eliminate this waiting time by handling all trailer positioning on-site.

Productivity Through Expertise

Professional spotters are not just drivers. They are trained to understand the layout of the facility, the flow of materials, and the critical timing of operations.

Benefits include:

-

Streamlined operations: Every minute saved on trailer moves contributes to a faster overall process.

-

Safety improvement: Experienced spotters know how to operate in busy yards with precision and care.

-

Reduced fuel and labor costs: Efficient movements mean fewer engine hours and less manpower wasted.

Technology and Tracking

Modern spotting services often use yard management software (YMS) integrated with GPS and RFID technologies. This allows:

-

Real-time tracking of trailer positions

-

Automatic updates to logistics teams

-

Data analytics for continuous improvement

By combining human expertise with digital tools, spotting services create a smart, responsive yard environment.

Industries That Benefit Most

While spotting services are beneficial across many sectors, they are especially vital in:

-

Food and Beverage manufacturing (where freshness and timing are crucial)

-

E-commerce distribution centers (due to high volume and rapid turnover)

-

Automotive factories (where supply chains are tightly timed)

-

Retail warehouses (to meet strict delivery windows)

Choosing the Right Spotting Partner

Not all spotting service providers are created equal. When choosing a partner, consider:

-

Experience in your industry

-

Availability of 24/7 support

-

Use of tracking and management systems

-

Ability to scale with your needs

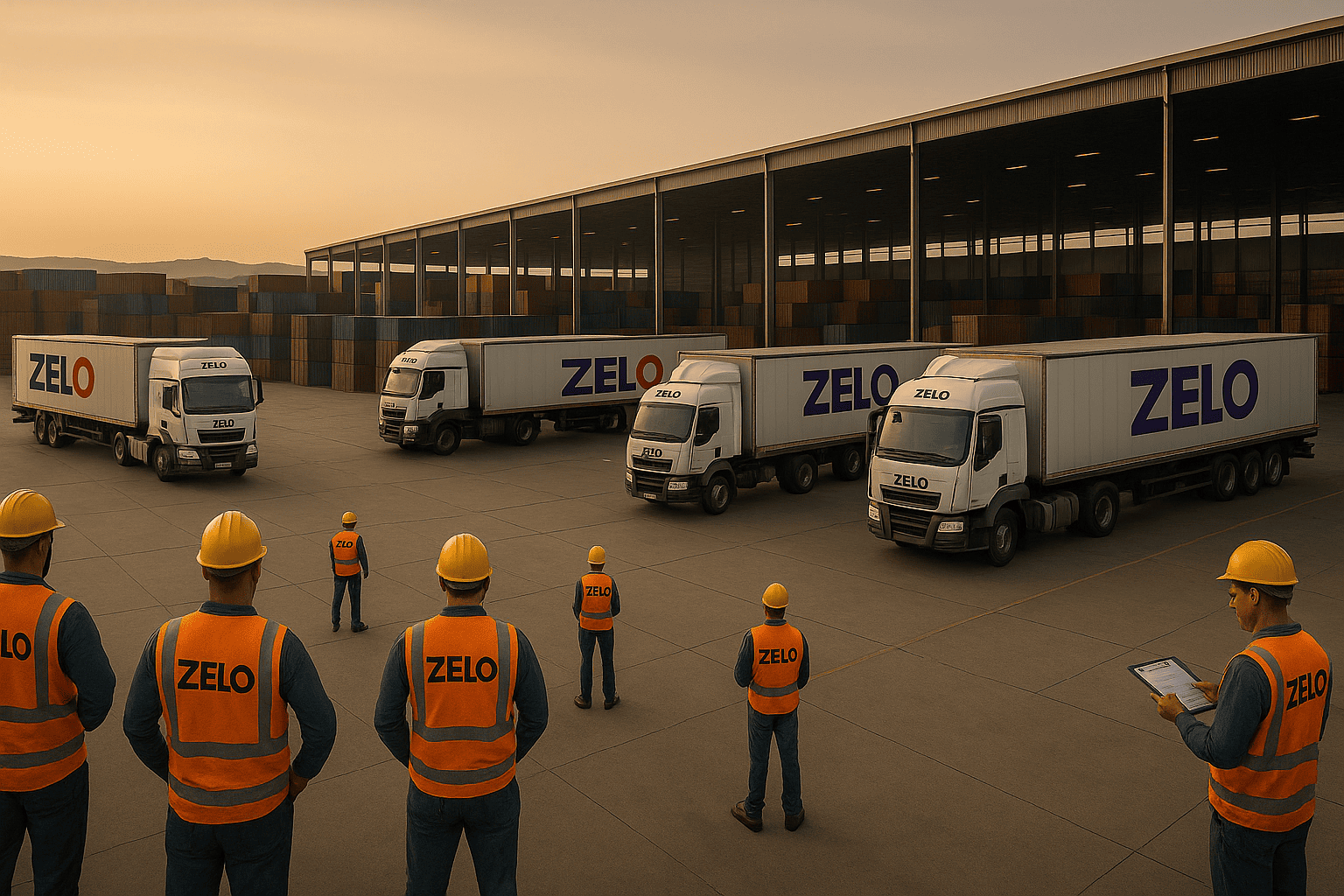

At Zelo Express, we specialize in tailored trailer spotting solutions that match the operational needs of factories and logistics hubs across Iraq. Our trained drivers, smart scheduling, and real-time management help reduce downtime and increase productivity.

Conclusion

In a competitive industrial environment, minimizing downtime is not just a goal—it’s a necessity. Spotting services provide a direct, effective solution by ensuring that trailers move efficiently, yards stay organized, and production lines run without delay.

Investing in professional spotting services is an investment in speed, safety, and success.

Let Zelo Express help you move smarter, not slower.